Navgraha Steels INC is a leading supplier of SA 516 Gr 70 HIC Tested Plates, Sheets & Coils, sourced from global mills like Sail, AMNS, JSPL, Evonith, Nippon Yakin, Outokumpu, Special Metals, VDM, and ATI. We specialize in providing hydrogen induced cracking (HIC) resistant boiler quality steel for refineries, petrochemical plants, and sour gas service. Every order is backed by MTCs, NACE compliance, and IBR approvals.

In refinery and petrochemical projects, the biggest risk is audit rejection due to missing NACE compliance.

In refineries and petrochemical plants, one of the biggest risks is material rejection due to non-NACE compliance.

In sour gas service, the wrong coil supply can destroy both timelines and credibility.

SA 516 Gr 70 HIC tested steel is designed to resist hydrogen-induced cracking, a common risk in environments containing wet H₂S (hydrogen sulfide). Unlike standard boiler quality plates, HIC-tested plates undergo specialized testing as per NACE TM0284 to ensure durability in sour service conditions.

Buyers choose HIC-tested plates when projects demand refinery safety, longer equipment life, and compliance with international oil & gas standards.

reactors, separators, tanks

pressure vessels exposed to sour gas

scrubbers, columns, exchangers

urea and ammonia plants

for crude oil and sour gas liquids

valves, pressure lines in high H₂S environments

| Property | Value (Typical) | Notes |

|---|---|---|

| Tensile Strength | 485–620 MPa | High strength under pressure |

| Yield Strength | ≥ 260 MPa | Ensures vessel integrity |

| Elongation | 17–21% | Ductile enough for fabrication |

| Impact Tested | -20°C (Charpy) | Optional, project-specific |

HIC testing ensures the plate maintains these mechanical properties even in hydrogen sulfide environments

| Element | Max % |

|---|---|

| Carbon (C) | 0.27 |

| Manganese (Mn) | 0.79–1.30 |

| Phosphorus (P) | 0.025–0.030 (lower for HIC resistance) |

| Sulfur (S) | 0.010–0.015 (low S enhances HIC resistance) |

| Silicon (Si) | 0.13–0.45 |

Plates are produced with low sulfur, low phosphorus, and clean steelmaking practices, ensuring resistance against hydrogen blistering and stepwise cracking.

SA 516 Gr 70 HIC tested plates comply with:

Global Equivalents

Brands We Stock:

Sail, AMNS, JSPL, Evonith, Nippon Yakin, Outokumpu, Special Metals, VDM, ATI

Buyers can choose from multiple mill origins to meet AVL (Approved Vendor List) approvals.

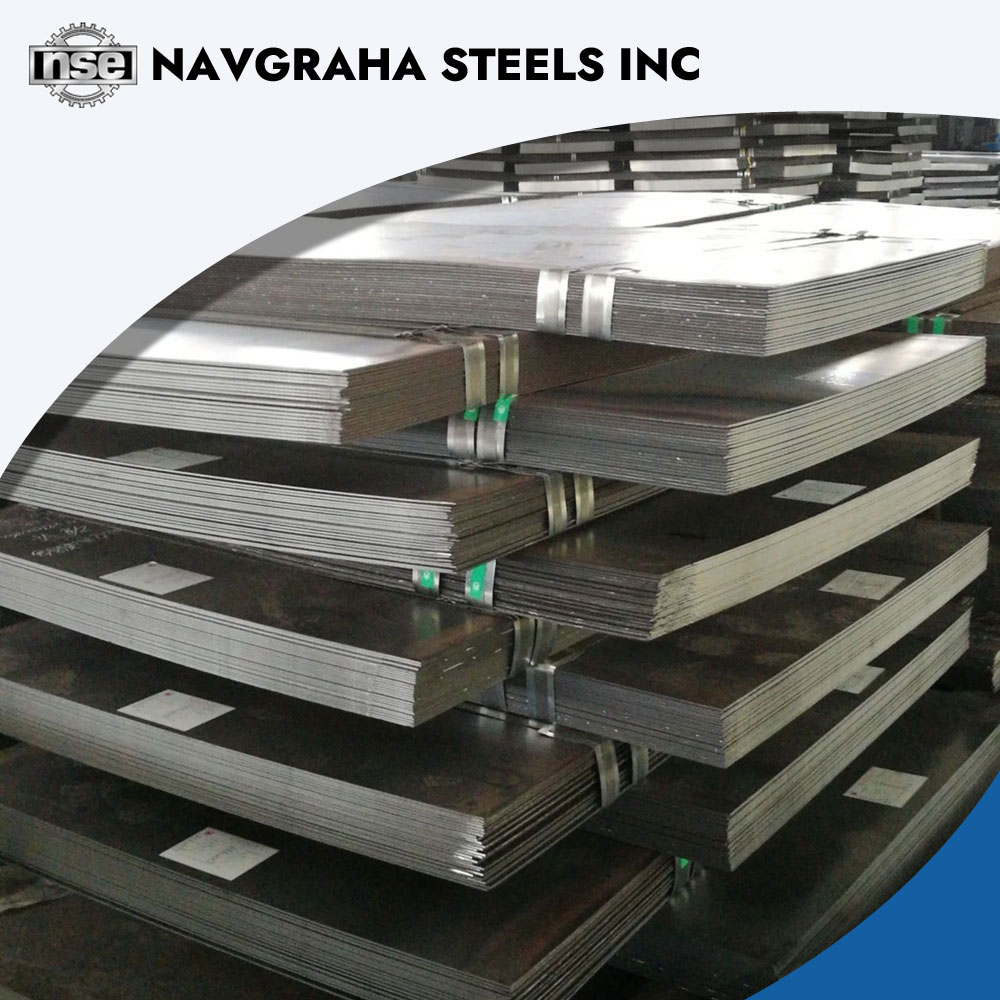

We maintain a wide range of HIC-tested stock:

This helps EPC contractors and refineries source exact project dimensions quickly.

This makes SA 516 Gr 70 HIC tested steel refinery-approved and project-ready.

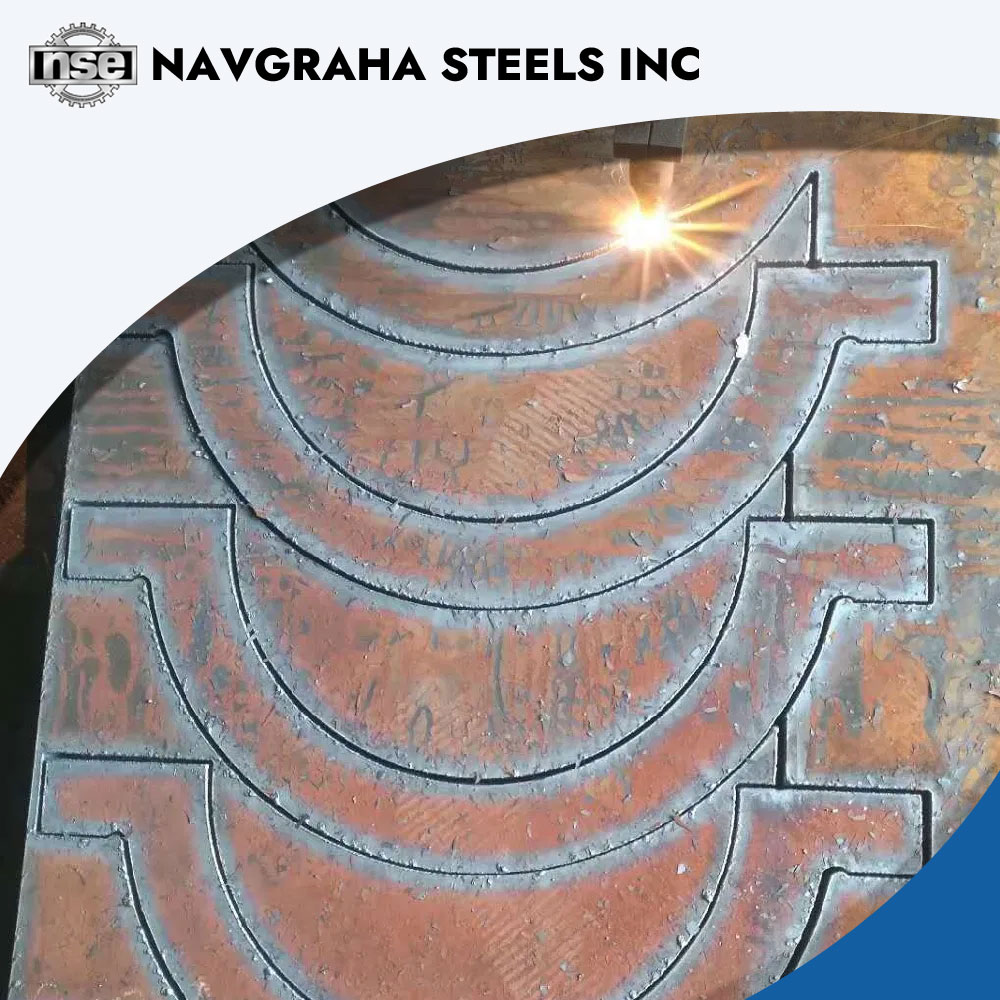

navgraha steels INC supplies fabrication-ready HIC-tested plates, reducing project delays

We help buyers eliminate compliance risk and procurement delays

Buyers receive project-ready steel with full compliance and inspection options.

navgraha steels INC exports SA 516 Gr 70 HIC Tested Plates, Sheets & Coils across global sour-service markets:

Packaging Standards:

Buyers receive safe delivery with refinery-ready certifications.

HIC-tested SA 516 Gr 70 should be selected when:

This ensures longer service life, lower maintenance costs, and global approval compliance

Every consignment of SA 516 Gr 70 HIC steel comes with:

Buyers receive traceable, project-ready steel with all required approvals.

It is boiler quality steel tested for hydrogen induced cracking resistance as per NACE TM0284.

Refineries, petrochemicals, sour gas environments, and offshore platforms.

HIC plates undergo special testing for hydrogen resistance, making them suitable for sour service.

Yes, we stock HIC-tested plates, sheets, and coils.

Sail, AMNS, JSPL, Evonith, Nippon Yakin, Outokumpu, Special Metals, VDM, ATI.

Yes, tested as per NACE MR0175/MR0103 standards.

Yes, IBR certified plates for boilers are available.

6 mm – 200 mm with custom cut-to-length options.

Yes, impact tested at -20°C can be supplied.

Yes, SGS, BV, Lloyd’s, TÜV inspections are available.

Low sulfur (≤0.010%) and low phosphorus (≤0.025%) for hydrogen resistance.

Yes, we export to GCC, Africa, Asia, and Europe.

Yes, we provide MTC and test reports upfront.

Price depends on thickness, certification, and mill origin—request a quote for latest rates.

Both small orders and bulk quantities are supplied.

Looking for SA 516 Gr 70 HIC Tested Plates, Sheets, or Coils?

With navgraha steels INC, you get:

or contact our team today.

WhatsApp us