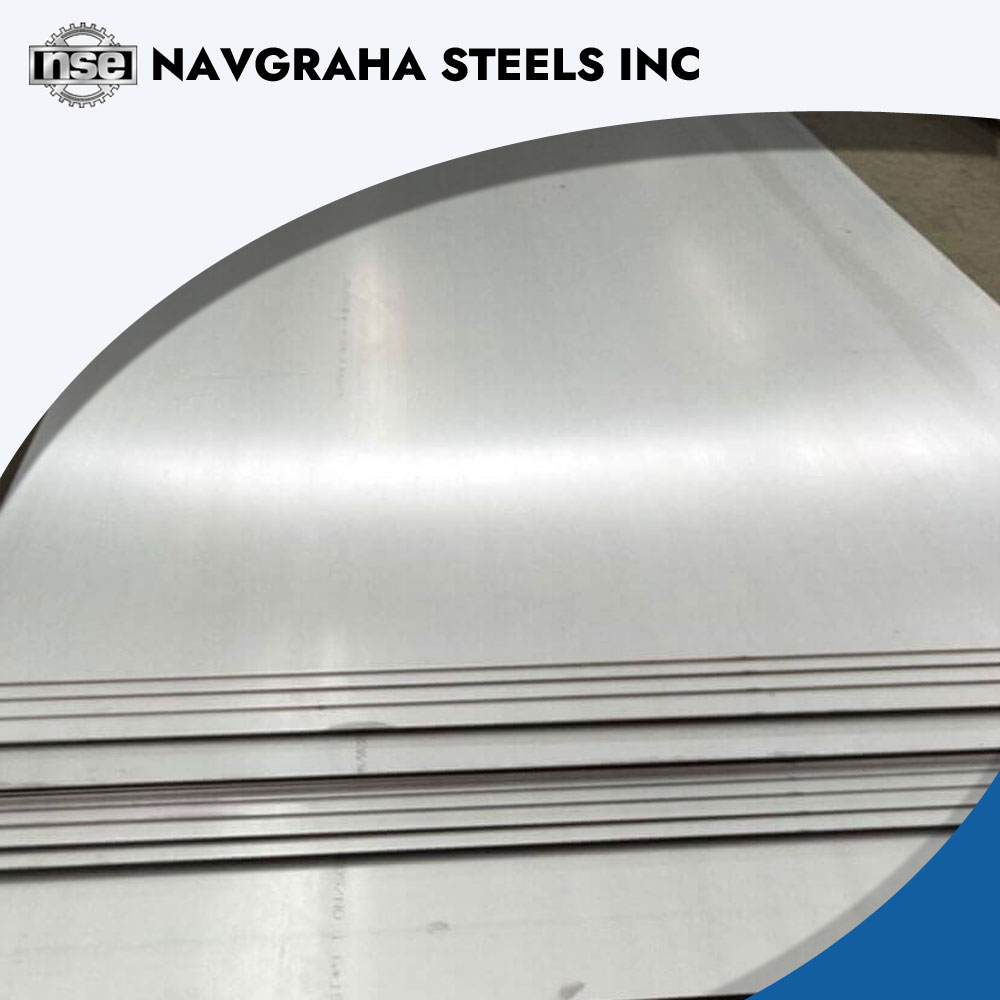

Navgraha Steels INC is a trusted supplier of Hastelloy C276 Plates, Sheets & Coils, sourced from global brands including Sail, AMNS, JSPL, Evonith, Nippon Yakin, Outokumpu, Special Metals, VDM, and ATI. Recognized as the most versatile nickel-molybdenum-chromium superalloy, Hastelloy C276 is engineered to withstand the most aggressive chemical environments. Our supplies are backed by EN 10204 3.1/3.2 MTCs, NACE certifications, and third-party inspections for complete buyer confidence.

In today’s EPC and industrial projects, a single wrong plate can derail an entire shutdown. Imagine ordering a Hastelloy C276 plate for a chemical plant

When it comes to EPC projects, refineries, or shutdowns, the last thing a procurement team can afford is wrong-grade or uncertified material.

In critical industries, one wrong material decision can lead to corrosion failures, shutdown delays, or project cost overruns. For procurement managers

Hastelloy C276 is a corrosion-resistant nickel alloy with high molybdenum and chromium content, designed to resist both oxidizing and reducing agents.

It is considered the industry benchmark alloy for reliability in severe industrial environments.

reactors, evaporators, heat exchangers, scrubbers

seawater handling systems, pipelines, and valves

flue gas scrubbers, stack liners, ducts

bleach plants, digesters, washers

equipment exposed to aggressive cleaning agents

sour gas service equipment, separators, and vessels

| Property | Typical Value | Notes |

|---|---|---|

| Tensile Strength | 690 MPa | High strength under load |

| Yield Strength | 283 MPa | Ensures durability under pressure |

| Elongation | 40–45% | Excellent ductility & formability |

| Hardness (Rockwell B) | ~95 HRB | Balanced hardness with machinability |

Provides a unique combination of high strength + ductility + corrosion resistance.

| Element | Typical Range % | Function |

|---|---|---|

| Nickel (Ni) | ~57 | Base alloy, corrosion resistance |

| Molybdenum (Mo) | 15–17 | Enhances resistance to reducing agents & pitting |

| Chromium (Cr) | 14.5–16.5 | Improves resistance to oxidizing agents |

| Iron (Fe) | 4–7 | Strengthens alloy balance |

| Tungsten (W) | 3–4.5 | Increases resistance to localized corrosion |

| Cobalt (Co) | ≤ 2.5 | Naturally occurring in nickel alloys |

| Carbon (C) | ≤ 0.01 | Ultra-low to prevent carbide precipitation |

Its balanced chemistry makes Hastelloy C276 one of the best all-purpose corrosion-resistant alloys available.

Hastelloy C276 is specified under:

Global Equivalents:

Available Brands:

Sail, AMNS, JSPL, Evonith, Nippon Yakin, Outokumpu, Special Metals, VDM, ATI

Ensures multi-mill sourcing, supporting global EPC and refinery approvals.

We supply Hastelloy C276 Plates, Sheets & Coils in:

Buyers receive customized dimensions to reduce fabrication time and costs.

Ideal for corrosive industries like flue gas scrubbers, bleach plants, and seawater systems.

Supplied in fabrication-ready condition, saving EPC buyers significant lead time.

Making Navgraha a preferred partner for corrosion-resistant alloy procurement.

Multiple variants make Hastelloy C276 suitable for chemical, marine, and pollution control industries.

Navgraha Steels INC exports Hastelloy C276 Plates, Sheets & Coils to global EPC contractors, chemical plants, and marine industries.

Major Export Markets:

Packing Standards:

Guaranteed safe, compliant, and damage-free export delivery.

Choose Hastelloy C276 when:

This makes Hastelloy C276 the “go-to” superalloy for aggressive environments.

Every order of Hastelloy C276 Plates, Sheets & Coils includes:

Ensures full traceability and international buyer confidence.

Chemical processing, marine seawater systems, scrubbers, and pollution control.

Yes, it offers far superior corrosion resistance in aggressive chemical media.

ASTM B575, UNS N10276, EN 2.4819.

Around 690 MPa.

~283 MPa minimum.

Yes, we stock plates, sheets, and coils.

Sail, AMNS, JSPL, Evonith, Nippon Yakin, Outokumpu, Special Metals, VDM, ATI.

Yes, it performs exceptionally well in marine environments.

Yes, MR0175/MR0103 certified plates are available.

Yes, it is highly resistant to SCC in chloride-bearing solutions.

Yes, SGS, BV, TÜV, Lloyd’s, DNV inspections can be arranged.

0.5 mm – 50 mm.

Yes, UAE, Saudi Arabia, Qatar & Oman are key markets.

~95 HRB (Rockwell B).

Pricing varies by thickness, certification & mill origin – request a quote.

Navgraha Steels INC supplies Hastelloy C276 Plates, Sheets & Coils with:

Fast export shipping to GCC, EU, USA, and Asia

or contact our team today.

WhatsApp us