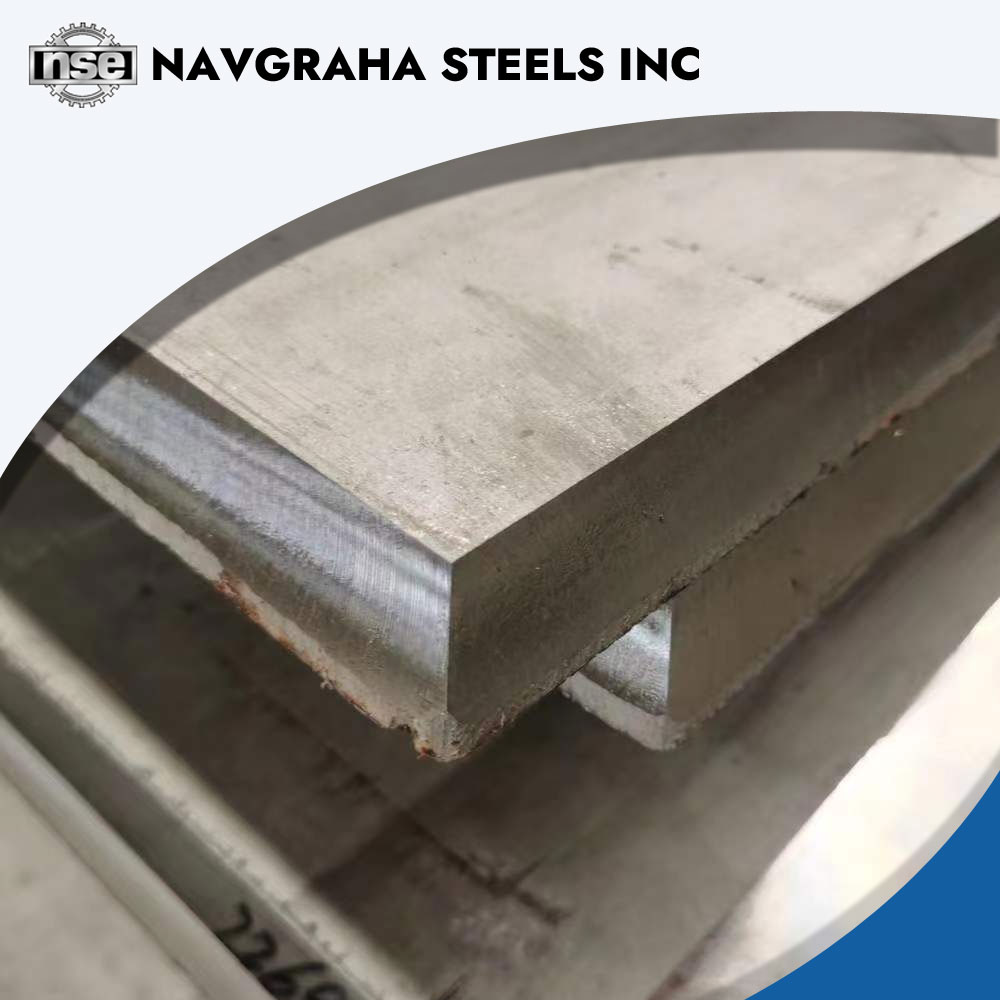

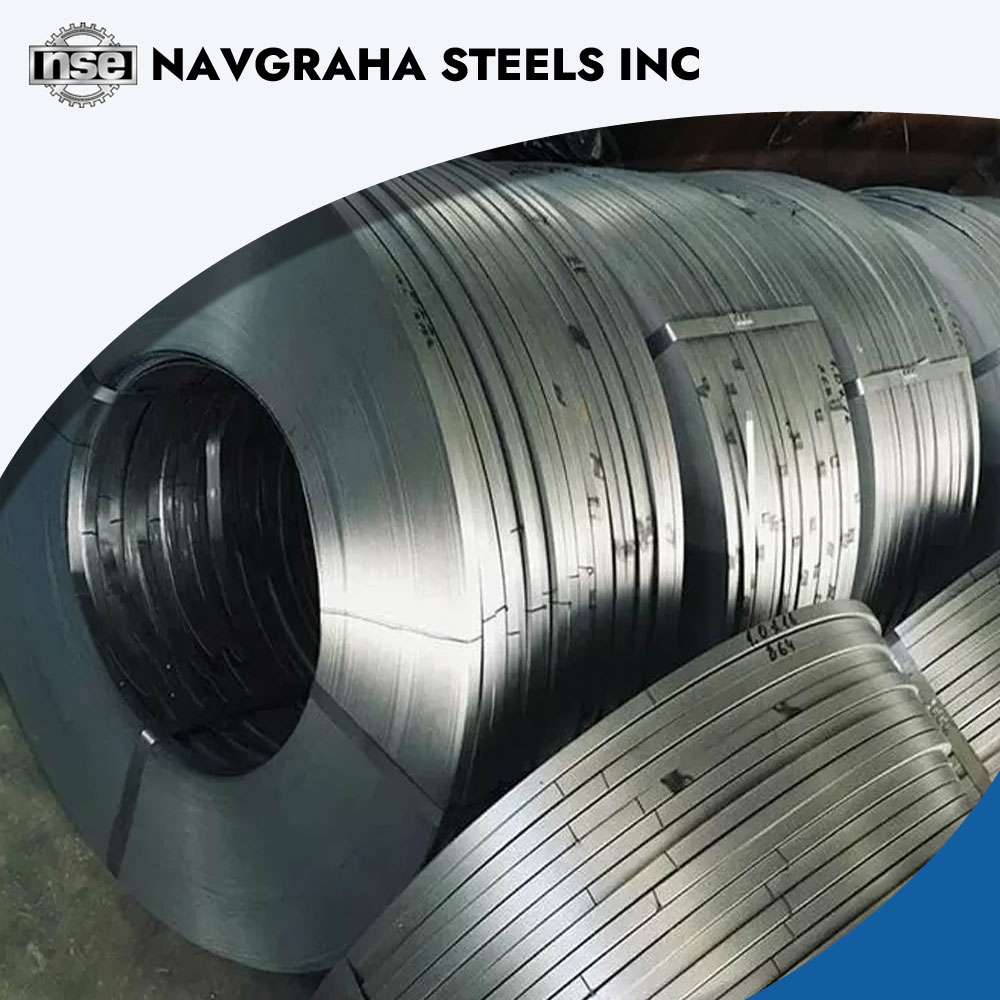

Navgraha Steels INC is a leading supplier of Monel 400 Plates, Sheets & Coils, offering material from world-class brands such as Sail, AMNS, JSPL, Evonith, Nippon Yakin, Outokumpu, Special Metals, VDM, and ATI. Known for its nickel-copper base alloy, Monel 400 delivers excellent performance in seawater, acids, alkalis, and high-temperature applications. Our stock is supplied with EN 10204 3.1/3.2 MTCs, ASTM compliance, and third-party inspections.

At Navgraha Steels INC, Mumbai, we supply Monel 400 Plates that are certified, export-ready, and globally approved, trusted in chemical plants, offshore projects, oil refineries, and energy industries worldwide.

At Navgraha Steels INC, Mumbai, we eliminate that risk with Monel 400 Sheets that are certified, corrosion-proof, and export-ready — trusted in marine, oil & gas, chemical, and energy industries worldwide.

At Navgraha Steels INC, Mumbai, we eliminate this risk with Monel 400 Coils — certified, seaworthy, and globally accepted. Our coils are trusted in marine, oil & gas, chemical, desalination, and energy industries across continents.

Monel 400 (UNS N04400, W.Nr. 2.4360/2.4361) is a solid-solution nickel-copper alloy with high strength and outstanding resistance to neutral and alkaline salts, seawater, and hydrofluoric acid.

Monel 400 is considered the gold standard material for seawater applications.

seawater valves, pumps, shafts, propeller blades

hydrofluoric acid vessels, alkali production, heat exchangers

sour gas piping, separators, refinery equipment

fuel tanks, turbine components

steam generators & condensers

evaporators, brine heaters

| Property | Typical Value | Notes |

|---|---|---|

| Tensile Strength | ~550–620 MPa | Good load-bearing capacity |

| Yield Strength | ~240 MPa | Reliable under pressure & stress |

| Elongation | ~30–40% | Excellent ductility |

| Hardness (Rockwell B) | ~75–85 HRB | Balanced machinability & strength |

A tough, ductile alloy ideal for marine & chemical plant conditions.

| Element | Typical % | Function |

|---|---|---|

| Nickel (Ni) | 63 min | Base element, corrosion resistance |

| Copper (Cu) | 28–34 | Enhances seawater & alkali resistance |

| Iron (Fe) | 2.5 max | Provides strength balance |

| Manganese (Mn) | 2 max | Improves hot working ability |

| Carbon (C) | 0.3 max | Controlled for weldability |

| Silicon (Si) | 0.5 max | Alloy balance |

This chemistry makes Monel 400 one of the most reliable marine-grade alloys.

Monel 400 is supplied under:

Available Brands:

Sail, AMNS, JSPL, Evonith, Nippon Yakin, Outokumpu, Special Metals, VDM, ATI

Buyers get access to multi-mill sourcing, ensuring global approval.

Flexible sizing options minimize wastage and fabrication time.

This makes Monel 400 a marine-grade alloy of choice.

Supplied in ready-to-fabricate form, reducing project delays.

A reliable partner for EPC contractors, refineries, and marine buyers.

Ensures tailor-made solutions for critical industrial environments.

Navgraha Steels INC exports Monel 400 Plates, Sheets & Coils to global EPC, marine, aerospace, and oil & gas clients.

Major Export Markets:

Packing Standards:

Ensuring safe, traceable, and compliant exports worldwide.

Select Monel 400 when:

Making it the best choice for marine, chemical, and refinery sectors.

Every supply of Monel 400 Plates, Sheets & Coils comes with:

Providing full assurance & global acceptance.

Marine equipment, chemical plants, sour gas service, and aerospace parts.

ASTM B127.

~550–620 MPa.

~240 MPa.

Yes, it is one of the best alloys for marine use.

Yes, it has excellent resistance to HF acid and alkalis.

Yes, along with plates.

Sail, AMNS, JSPL, Evonith, Nippon Yakin, Outokumpu, Special Metals, VDM, ATI.

Yes, available for sour gas service.

Yes, with good weldability using Monel filler wires

~75–85 HRB.

Yes, UAE, Saudi Arabia, Oman, and Qatar are major markets.

0.5 mm – 50 mm.

Monel 400 offers far better resistance in seawater & non-oxidizing acids.

Depends on size, thickness & certifications – request a quote.

Navgraha Steels INC supplies Monel 400 Plates, Sheets & Coils with:

Worldwide delivery across GCC, Africa, EU, USA & Asia

or contact our team today.

WhatsApp us